How Modern Diesel Engines Leave Power on the Table From the Factory

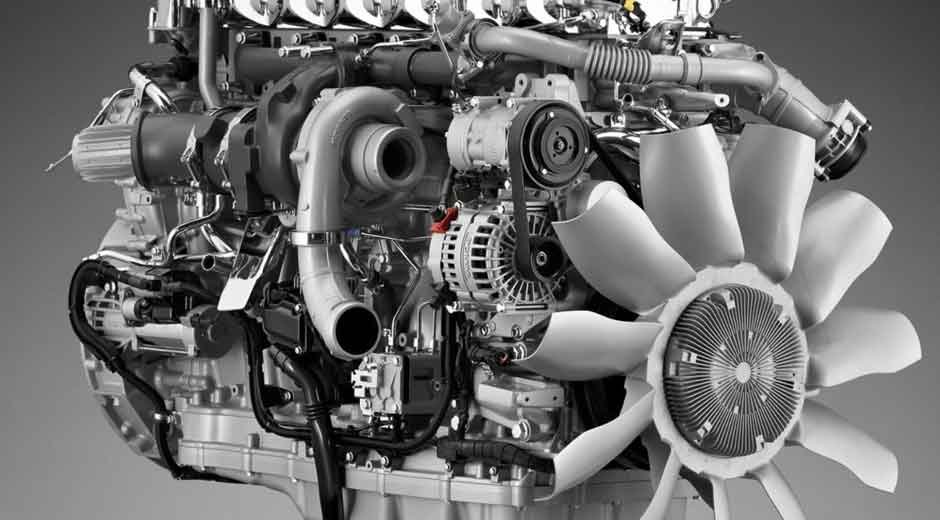

Modern diesel engines, particularly those in heavy-duty trucks, are impressive pieces of engineering. They produce substantial power, impressive torque, and can tow enormous loads. Yet despite these capabilities, they’re operating well below their actual potential when they leave the factory. This isn’t a design flaw or manufacturing limitation. It’s intentional.

Manufacturers deliberately limit diesel engine performance for various reasons that have little to do with what the engine can actually handle. Understanding why these restrictions exist and how much performance is being held back helps explain why diesel tuning has become so popular and why the results can be so dramatic compared to stock configurations.

The Emissions Regulations That Changed Everything

Emissions requirements have become increasingly strict over the past two decades, particularly for diesel engines. Meeting these standards requires careful management of combustion temperatures, fuel delivery, and exhaust gas treatment. The cleanest-burning configuration isn’t always the most powerful one.

Manufacturers tune engines to pass emissions tests and meet regulatory requirements across their entire production run. This means conservative fuel maps, limited boost pressure, and exhaust gas recirculation settings that prioritize clean exhaust over maximum power. The engine is physically capable of much more, but the factory calibration keeps it restrained to stay within emissions limits.

This creates a situation where the hardware (turbocharger, fuel system, engine internals) is built to handle significantly more stress than the factory tune allows. The gap between what the engine can do mechanically and what it’s allowed to do electronically is often substantial. That gap represents the performance potential that aftermarket tuning can unlock.

Warranty and Liability Concerns

Automakers need their engines to last reliably for hundreds of thousands of miles under warranty. They also need to avoid liability issues from engines that fail prematurely or cause accidents. The safest approach is building in significant safety margins, which means limiting performance below what the engine could theoretically produce.

A stock tune includes buffers to account for variations in fuel quality, maintenance practices, driving conditions, and manufacturing tolerances. Not every diesel engine rolls off the assembly line with identical specifications. Some have slightly better turbos, others have fuel injectors that flow a bit differently. The factory tune has to work reliably across all these variations, so it’s calibrated conservatively.

This conservative approach extends engine life and reduces warranty claims, but it also means most engines are operating nowhere near their mechanical limits under normal conditions. There’s headroom built into virtually every parameter, from boost pressure to fuel delivery to cylinder pressure. Performance tuning takes advantage of this headroom.

The One-Size-Fits-All Problem

Diesel trucks get used for everything from daily commuting to heavy towing to commercial work. The factory tune needs to work reasonably well across all these use cases, which means it can’t be optimized for any single purpose. It’s a compromise that serves the average user but doesn’t excel at anything specific.

Someone who primarily uses their truck for towing would benefit from different tuning than someone who races or someone who just drives to work. The factory can’t customize tunes for individual use cases at the production level, so they settle on settings that work adequately for everyone but aren’t ideal for anyone. A cummins diesel tuner allows customization that the factory simply can’t provide at scale.

This explains why aftermarket tuning can produce such noticeable improvements. When the tune is optimized for how someone actually uses their truck rather than trying to satisfy every possible scenario, the performance gains can be dramatic. The engine isn’t limited by what it might need to do someday, it’s calibrated for what it actually does.

Market Segmentation Strategy

Here’s something that doesn’t get discussed much but matters quite a bit. Manufacturers intentionally limit lower-tier engines to protect sales of their higher-performance models. If a base diesel engine performed too close to the premium version, why would anyone pay extra for the upgrade?

This means engines in lower trim levels often have the same or very similar hardware as more expensive models but with different electronic limitations. The physical capability is there, but the factory tune restricts it to maintain product differentiation. Buyers pay thousands more for upgraded models that sometimes differ primarily in software rather than hardware.

From a business perspective this makes sense, but it also means tremendous performance potential is being artificially limited. The engine in a work truck might be nearly identical to the one in a premium model but produce significantly less power simply because of how it’s programmed. Aftermarket tuning can eliminate these arbitrary restrictions.

Fuel Economy Standards and CAFE Requirements

Corporate Average Fuel Economy standards pressure manufacturers to maximize efficiency across their vehicle lineup. This affects diesel tuning in ways that aren’t immediately obvious. To improve fuel economy numbers, engines run leaner air-fuel ratios and lower boost levels than they would if power was the only priority.

The result is engines that perform adequately but not exceptionally in stock form. They meet or exceed EPA fuel economy estimates, which helps the manufacturer’s fleet average and avoids regulatory penalties. But this efficiency-focused tuning leaves power on the table that could be accessed with different calibration priorities.

Interestingly, many diesel owners report that proper performance tuning doesn’t necessarily hurt fuel economy and can sometimes improve it. When the engine produces power more efficiently, it doesn’t have to work as hard to achieve the same results. This challenges the assumption that performance and efficiency are always in opposition.

The Built-In Safety Margins

Modern diesel engines are engineered with impressive durability. The blocks, pistons, rods, and other internal components are designed to handle far more stress than stock power levels create. This over-engineering serves multiple purposes, including reliability and longevity, but it also means the mechanical limits of the engine are well above what the stock tune allows.

Turbochargers on factory diesels rarely operate anywhere near their maximum flow capacity in stock configuration. Fuel systems can deliver more fuel than the stock tune requests. Transmissions are built to handle more torque than the engine produces from the factory. All these systems have headroom that exists primarily as safety margin.

These margins exist for good reasons. They account for age, wear, poor maintenance, and abuse. But for someone who maintains their truck properly and understands the trade-offs, those margins represent accessible performance. The engine can safely handle more power than it’s making in stock form, often substantially more.

The Aftermarket Reality

The gap between factory performance and actual engine capability has created a thriving aftermarket tuning industry. Companies have figured out how to access the restricted performance while managing the various concerns (emissions, reliability, driveability) that caused manufacturers to limit things in the first place.

Modern tuning isn’t just about cranking up boost and dumping in more fuel. Quality tuning carefully adjusts dozens of parameters to extract more performance while maintaining reliability and reasonable emissions. The goal is finding the sweet spot between what the engine can handle and what produces the best results for how the truck gets used.

This explains why tuning results can vary so dramatically. A mild tune that prioritizes reliability and daily driveability might add 50-75 horsepower. An aggressive race tune on the same engine might add 200+ horsepower. The engine was capable of both all along, but the factory tune kept it operating in a narrow, restricted window.

Understanding the Trade-Offs

None of this means factory tunes are wrong or that everyone should immediately tune their diesel. Those factory limitations exist for legitimate reasons. Emissions matter. Warranty protection matters. Reliability across various conditions and users matters. Not everyone needs or wants maximum performance.

But understanding why modern diesels are limited helps explain the huge performance gains possible through tuning. It’s not that aftermarket tuners are magicians creating power from nothing. They’re accessing capability that was already there but restricted. The engine had that potential all along, it just wasn’t being used.