The Heartbeat of Your Engine: A Deep Dive into Timing Belts

You don’t have to be a mechanic to know that regular maintenance is what keeps your car running smoothly. Engine parts that are designed to keep everything working in sync, such as timing belts, ensure proper performance when you need it and prevent costly repairs if serviced on time.

What Are Timing Belts?

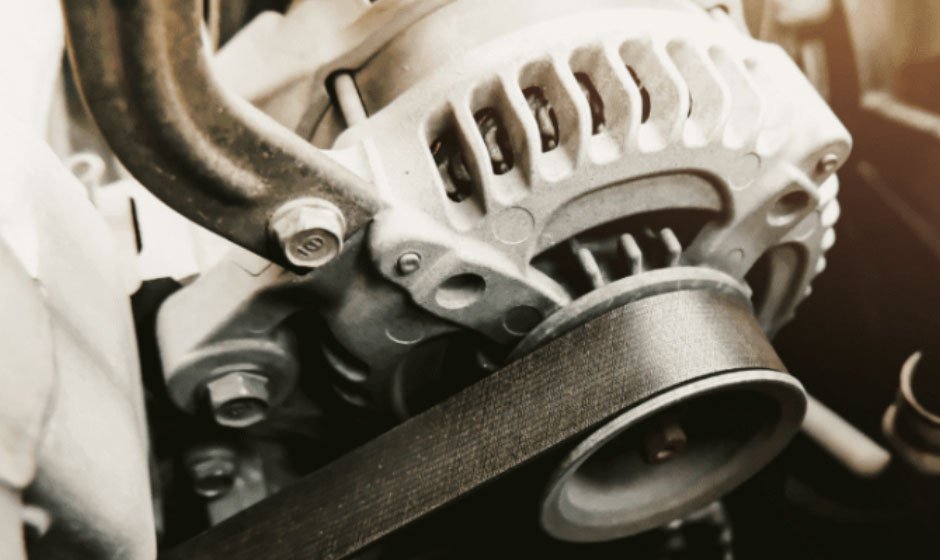

Timing or cam belts are essential engine components that synchronize the work of the crank and camshaft(s). They consist of a defined number of teeth that interlock with the crank pulley and the cams to ensure that they turn at the same time. This helps the camshaft to lower and lift the inlet and exhaust valves simultaneously with the pistons, thereby facilitating the combustion process. Pistons are in the correct position in each engine cycle, and valves open and close at precisely the right time.

Connected to the crankshaft pulley, engine timing belts are also involved in related engine processes. Crank rotation provides the momentum to turn the belt and other necessary components, like water and oil pumps, to enable engine cooling and lubrication.

When to Replace Them

No engine part lasts forever, and the same applies to timing belts. Though tough, they can start to show signs of wear and affect how the car performs. General recommendations are to replace the belt at intervals between 40 and 100 thousand miles, or within 5 years, depending on the engine, stock belt and how you drive. Most belts will provide smooth and quiet operation within these timeframes and distances, but some can fail early on. Driving with a faulty belt is possible, but you risk major damage to the internals if it fails.

Signs of Faulty Belts

An engine timing belt can break without obvious warning signs. But minor cracks, worn teeth and stretched or misaligned belts are usually easy to spot, even before popping up the hood. The most frequent signs that you’ll need a replacement include:

- Misfires – the basic role of engine timing belts is synchronization. Spark plugs firing at the wrong time, off compression rates, and lean fuel mixtures can cause shudders, vibrations and sudden loss of power.

- Ticking noises – these can usually be heard when belt teeth have worn to the point that they slip along the crank pulley.

- Oil leaks – with auxiliary parts like oil pumps relying on belts, any damage can lead to oil dripping under the engine bay. Related is black exhaust smoke, with the engine burning oil instead of fuel.

- Loss of power and erratic performance – difficulty accelerating, the engine not building speed and sudden changes in RPMs can mean a worn belt. This is also evident with rough idling. And if the car stalls and the engine doesn’t turn over, you know what to blame.

There are many reasons why these issues occur. Misaligned belts, tooth wear, bad tracking, loss of tensile strength, and loose or worn tensioners and pulleys are usually the main culprits. This can further accelerate damage and cause loose belts and skipping teeth. Belts in modified engines are also known to have issues with higher torque and engine loads, often leading to uneven wear and abrasion.

Choosing the Right One for Your Car

Replacement belts come in different grades, designs, tooth profiles and varying materials to suit a variety of driving applications. They also need to be sized correctly and provide the required tension. Materials, designs and size are the three main factors to consider when choosing a replacement.

Materials

Materials have a huge say in how the belt performs, how it deals with elongation and tension, and how long it lasts when faced with typical nasties like high temperatures, exposure to oil and water, abrasions and impact. Chloroprene belts are featured in older vehicles with lower operating temperatures between 175 and 190 Fahrenheit and lower engine speeds. The material was sufficiently flexible, with good elongation, and performed generally well under loads, but low oil resistance caused brittleness and surface cracks, leading to premature wear.

Synthetic rubbers like HSN (highly saturated nitrile) and HNBR (hydrogenated acrylonitrile butadiene rubber) have largely replaced these. HSN has more tensile strength to work efficiently under higher loads and engine temperatures of up to 230 °F. HNBR is the latest iteration of engine timing belts, building on the pros of HSN and adding very high abrasion and impact resistance for improved longevity, increased heat resistance and minimal friction rates for low noise and smooth operation.

The synthetic rubbers are also combined with other materials, such as Teflon in the belt jackets and Kevlar in the tooth profiles, for reduced wear. These are often found in interference engines, where their high strength prevents piston crowns and valves from smashing against each other if belts slip or snap.

Sizes and Designs

Belt sizes are calculated by multiplying the number of teeth by the belt pitch, or the distance between the ridges created by one tooth and the next. This varies for different engines and vehicles and is either engraved on the belt itself or on the pulley tensioners. Widths are also consistent. OE variants have the same tooth count and pitch rate, and this is what to go by when looking for a new belt.

Designs and tooth profiles have also changed throughout the years, moving from conventional trapezoidal teeth, which, while adequate at lower RPMs and loads, have been known for high wear due to increased stresses the belts face in contact with pulleys. Curvilinear tooth profiles have led to longer-lasting belts and lower stress levels, while also lowering noise, specifically at higher engine speeds. Current designs revolve around modified curvilinear tooth profiles with more circular shapes that aid in better torque transmission.

Packaged Deals

Belts can be purchased on their own or are more commonly sold as packaged kits, including water pumps, tensioners and idler pulleys. Since all parts endure roughly the same rate of wear and are interdependent, a good idea is to also replace tensioners and pulleys and the water pump at the same time as the belt to ensure consistent performance. This also means you’ll be saving on labour costs. Just ensure the parts and belts are compatible with your vehicle.